I spent 4 months at FGC from early November until the end of February. It was a good experience for me to be exposed to the multitude of PLC system vendors and SCADA. I managed to complete a few small projects, but unfortunately none of them involved an automation system.

That’s why I moved to MadoX Technologies, mostly because it's a system integrator. Working for a system integrator has its own challenges, and I got the opportunity to learn MadoX's specialty: the ABB AC 800M Controller and programming the 800xA DCS System. My current official title is DCS Engineer, and it has been 4 months now at MadoX. It was a bit rough at first since not so many projects were present, but now new projects keep coming in.

A perfect example of this new work is the on-site support I provide for Annual Maintenance Contracts (AMCs). It is generally a predictive maintenance service done on both the hardware and software sides of the automation system.

"PPE, tools, PTW, checklist... what else?"

There are a couple of things that need to be checked and ready before you arrive on-site, otherwise you're going to waste a lot of time.

PPE varies a bit from client to client. It also depends on the size of the client's site and workforce. For example, according to the general color-code for safety helmets, I'm supposed to wear a white one, but this only applies if the client site doesn't have its own regulation. The same goes for other PPE, like whether to wear safety glasses or goggles. Always check the client's site requirements first; otherwise, default to the standard gear.

For tools, I just bring what I used during my time at FGC. My multimeter is a sanwa PM3, though I'd rather use one with a magnet or clamp. Being able to attach it to something while probing is a huge help when you're working alone.

And don't forget to raise a Permit To Work (you know the drill), and to bring the maintenance checklist. This checklist, which you've prepared beforehand, acts as your guideline for what to inspect, measure, and maintain.

Sounds simple, right? The tasks I covered during my on-site AMC support can be separated into two parts: panel maintenance and workstation maintenance. It's important to note that the actual checklist is tailored to each client's needs, but the overview below covers the general scope.

Panel Maintenance

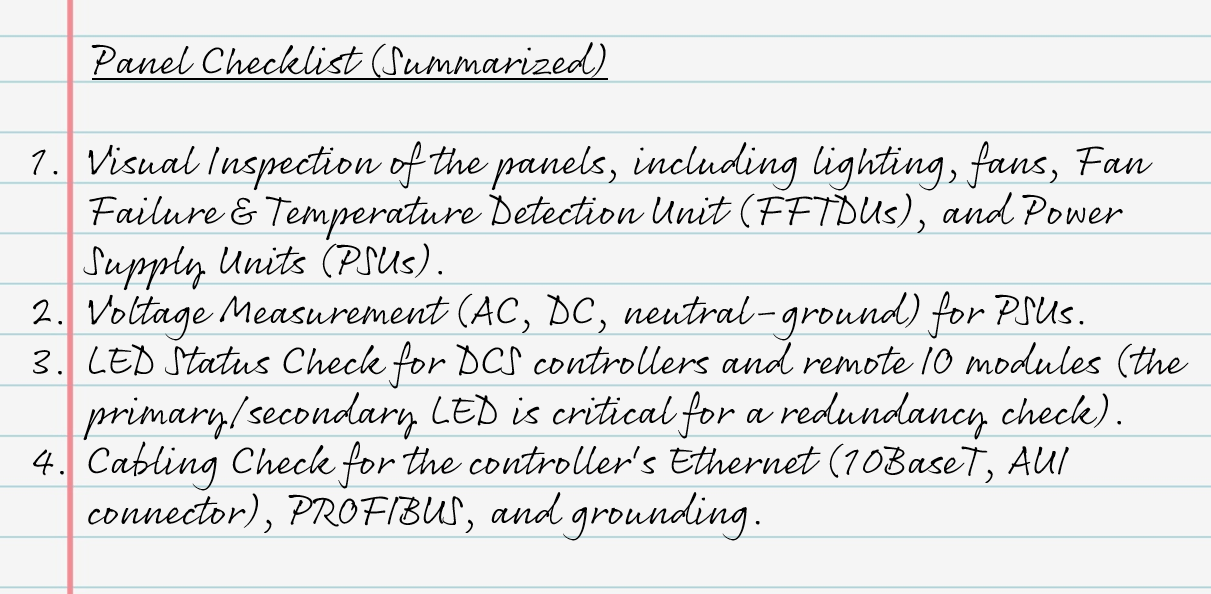

On the first day of a site visit, I focus on the panel inspection. Depending on the client's layout, some sites will have automation system panels in one centralized control room, while others have several control rooms spread out across the site. The tasks involved in panel maintenance are summarized as follows:

One key thing about DCS systems is the number of redundancies involved (controller redundancy, Profibus line redundancy, power supply redundancy). It's essential to understand the electrical components inside the panels and the electrical drawings to evaluate risk and propose suitable recommendations if a component is found to be faulty.

Workstation Maintenance

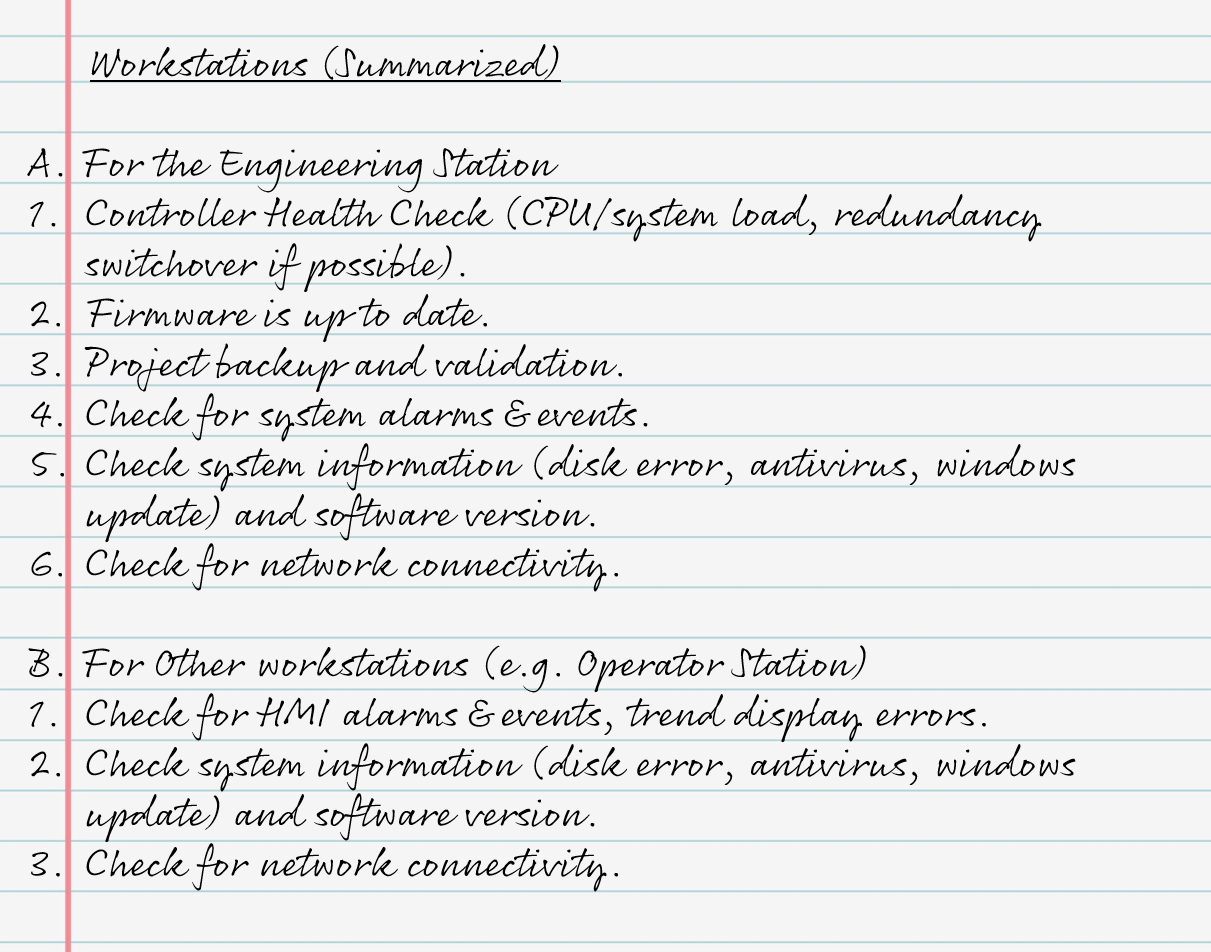

Unlike panels, workstations tend to be centralized in a single control room. Workstations maintenance are a bit different, in the sense that you need to understand the system architecture and topology to better evaluate your assessment during maintenance. This distinction becomes critical when problems arise.

For example, on the hardware side, if a Power Supply Unit (PSU) is found to be faulty, the solution isn't always immediate. There's a high chance a faulty unit won't have a spare part on site and will need time to be ordered. On the software side, however, the expectation is different. There's generally no external excuse for failing to rectify a problem, as the solution often comes down how well you understand the system (read: skill issue).

With that context in mind, the workstation maintenance tasks are summarized as follows:

Similar to the panels, it's crucial to understand the redundancies (in this case, network redundancy). If present, you need to perform a switchover to validate the redundancy functionality.

Once the data collection from all the above steps is complete, creating a report is necessary for client review and clarification.

Summary

I'm not gonna lie, doing an on-site AMC with just one person and a two-day limit was pretty rough. You're under pressure to cover all the panels and workstations, but I'm pretty sure things get easier once you get familiar with the specific environment, the panel layouts, and the tasks.

Overall, this on-site support is a great opportunity to understand automation systems on a deeper level. You see firsthand how each client's setup is unique, built around their specific needs. Some have robust redundancy and complex network configurations, while others take a more simple approach.

I gained good hands-on electrical experience from my time at FGC, but understanding system topology and troubleshooting workstations requires a different skillset, often leaning into IT knowledge. For someone working in Operational Technology (OT), I wonder, is it worth taking a crash course on networking? I might as well get a cert if there is one.